Heat Exchanger – Spray Continuous Pan

- Home

- Heat Exchanger – Spray Continuous Pan

Spray Continuous Pan (SCP®)

Crystallization consumes major portion of heat energy in a Sugar Manufacturing Process. Spray Continuous Pan (SCP®) is efficiently developed for optimizing evaporative crystallization of sugar solutions. Vertical Continuous Vacuum Pan (SCP®) offers high efficiency without any compromise on the process parameters. Multi-chambered mechanically stirred Vertical Continuous Pan has several advantages over Horizontal Continuous Pans.

Process Performance Parameters Of Scp

| DESCRIPTION | PARAMETER |

|---|---|

| Total Height of SCP® | 25-35 m |

| Diameter of Calandria | > 4 m |

| Heating Surface per Chamber | 250-1000 m² |

| No. of Chambers | 3-8 Nos. |

| Provision for Graining | 2 Chambers |

| Total Holding Volume per Chambers | > 50 m3 |

| Designed Heating Steam Temperature/Pressure | 65-90°C/ 25-70 kPaA |

| Designed Outlet Vapour Temperature/Pressure | 40-60°C / 7.5-20 kPaA |

| Feed Liqour Concentration | 60-85 % (Total Solids) |

| Effective Temperature Difference between Boiling | 5-25°C |

| Crystal Content Range | 30-60 % |

| Massecuite out | By gravity to Pug Mill |

Distinct Features:

- Suitable for all types of massecuites (Raw, Refined, A, B and C).

- Operates with low pressure vapours of 200 mbar – 500 mbar.

- Essential wetted parts in stainless steel to reduce colour additions.

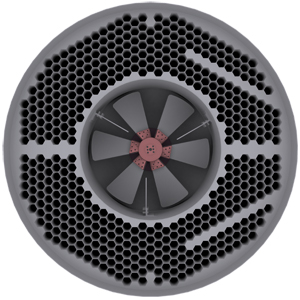

- Bottom mounted Mechanical Circulator for uniform crystal size.

- Compact size with self supporting structure.

- Honeycomb calandria for improved circulation.

- Minimum Coefficient of Variation (C.V.) [28-30]

- Liquor handling from 50 – 85% concentration due to vigorous circulation.

- Sugar yield of Pan – 55% - 60% with 90-91% brix.

- Chamber bypaas arrangement for CIP. Fully automated intelligent system for precise operation.

- Flexibility of including seed pan and receiving crystallizer within the tower (optional).

- Flexiility to operate on overflow or bottom discharge.

- Modular chamber pre-fitted with instruments to reduce erection time.

Process Advantages:

- Better massecuite quality

- Improved sugar recovery

- Improved evaporation and crystallization rates with low temperature / pressure vapours Continuous operation with online cleaning

- Lesser hydrostatic effect

- Provision of seed pan with uniform seeding

- Availability for all process ranges.

Steam & Power Economy/ Energy Efficiency

Steam economy:

SCP can operate with vapours of 300mbar – 500mbar (~85 deg C) vapour bled from 3rd or 4th effect of evaporator train. Capability to operate with low temperature vapours ensures process steam economy.

Power economy:

The installed power for complete unit is around 250 – 275 kW. Less operating power required because of planetary drive circulators fitted with VFD.

Design Advantages:

- Compact modular single tower design

- Complete instrumentation

- Stainless steel wetted parts

- Light gauge self-supported structure

- Vertical installation

Control Advantages:

The control scheme of a continuous pan is quite different from a batch type pan. SCP has all essential instrumentation that gives flawless performance.

- Ease of operation.

- Integration with any third party control system.

- Provision for flow, temperature, pressure, level and consistency measurement for each chamber.

- Process parameters control for individual chambers.

- Fail safe provisions in case of error / failure.

- Inbuilt historic alarms, historic trends and report generation provision.

- Auto cleaning / rinsing cycle of valves & sensors to minimize shutdowns.

- Individual control of vapor in and out to achieve consistent boiling.

Support and services are available 24 x 7 by email at sales@acryo.com.au